Published on the 26th November 2014 by ANSTO Staff

ANSTO's nuclear medicine program supplies products for the treatment of one in two Australians and many more people worldwide.

In Tokyo an anxious 42-year-old woman faces breast cancer surgery. She has just had a tiny amount of the radioactive element technetium-99m injected into her breast ahead of a scan that will tell her surgeon which lymph nodes to biopsy – thereby increasing the effectiveness of her operation.

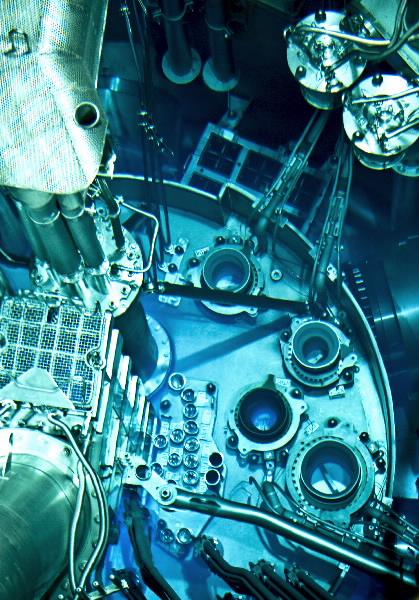

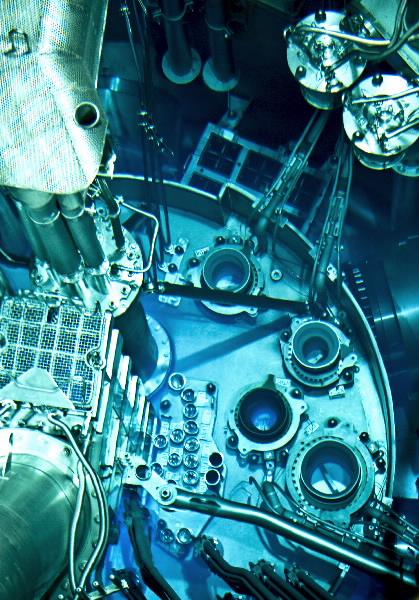

She doesn’t know it, but her scan relied on ANSTO’s OPAL reactor in Sydney, which was designed for nuclear medicine and research.

Radioactive molybdenum-99 (which decays to make technetium-99m), arrived at the airport just in time to get through customs and onto a Qantas flight to Tokyo. On landing, it was rushed to a nuclear medicine processing company, where it was incorporated into a ‘generator’ – a heavily shielded device about the size of an esky – then couriered to the hospital, where the minute dose of technetium needed for her scan was drawn off.

ANSTO has the process of sending time-critical nuclear medicine supplies across the globe down to a fine art, regularly shipping molybdenum-99 to Asia and the USA.

“We can get product from Sydney to Boston as efficiently as it can be shipped there from Europe,” says Shaun Jenkinson, ANSTO Nuclear Business Group Executive.

With radioactive elements, time is of the essence. Technetium-99m has a half-life of just six hours, which means half of it will have decayed into something else in that time. This is why it is shipped as its precursor, molybdenum-99, which has a half-life of 2.75 days.

ANSTO’s molybdenum-99 exports bring in over $10 million each year to Australia. This figure is set to triple after 2016, when its new $100 million nuclear medicine processing facility starts up, bringing with it 250 new jobs.

“This will allow us to provide about 25% of the global volume of molybdenum-99 and, with our joint venture South African partners NTP, supply about 50% of the world market,” Jenkinson says.

Most of the main reactors producing nuclear medicines are fuelled by highly enriched uranium (HEU) in the U-235 isotope, as well as HEU ‘target plates’ for making molybdenum-99. HEU is also a critical component for nuclear weapons. Hence, the use of HEU is discouraged in accordance with an international treaty on the non-proliferation of nuclear weapons.

The OPAL reactor, however, is technologically advanced in that it uses low-enriched target plates when making molybdenum-99 and runs on low-enriched uranium fuel, which cannot be diverted to weapons.

“We lead the way – being good citizens of the world by supplying a product that’s proliferation-proof,” says Jenkinson.

In Australia, ANSTO is the major supplier of technetium-99m in nuclear medicine. “About 600,000 Australians have nuclear medicine scans every year,” says Professor Paul Roach of the Royal North Shore Hospital in Sydney.

Since only minute amounts are needed for each scan – including bone, cardiac, lung, thyroid and kidney scans – the entire Australian market uses just 60 ml of molybdenum-99 per week. But not all nations are self-sufficient in this way.

“There have been real issues in the USA when people have struggled to get technetium because the old reactors have been down for repair,” says Roach.

As North America’s older reactors retire from service over the next two years, ANSTO is well-placed to increase its output, and take up the challenge of providing the necessary medical exports to a growing global market.

This story was first published in issue 4 of Know How magazine.