ANSTO’s suite of infrastructure and capabilities is ideally suited for solving problems relating to the development and characterisation of advanced materials, the engineering of manufactured components and manufacturing processes for the aerospace and space industries.

This includes the engineering of critical components under unusual operating conditions, including predicting critical weld failures, creep-fatigue and corrosion, repair to metal surfaces using laser cladding; manufacturing carbon-fibre materials; the optimisation of coatings, and the 3D printing of complex metal components.

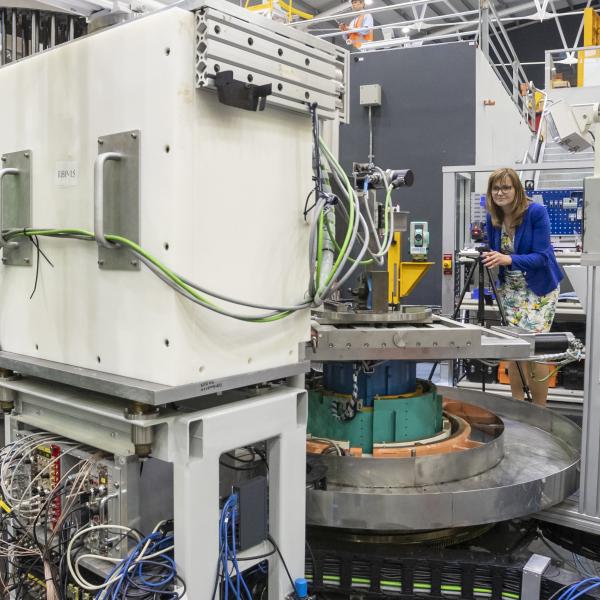

Our instruments provide critical information and images about defects that can be used to investigate texture and operating conditions, as well as provide assessments of dimensional tolerances.

Residual stress measurements and in situ studies of the thermo-mechanical properties using neutrons and X-rays can provide information not available using other techniques.

Capabilities include computational modelling.