Published on the 15th August 2016 by ANSTO Staff

This past week, the KOWARI strain-scanner team has been busy investigating parts for Metal Industries Research & Development Centre (MIRDC) in Taiwan. The aim is to understand how residual-stress affects the stability and reliability of the critical components designed to perform in modern Additive Manufacturing machines.

MIRDC is a long-standing, non-profit organization that focuses on researching and developing the leading technologies of metal and related industries in Taiwan. The main service fields of MIRDC include the basic-metal industry, the metal-products industry, the machinery industry, electrical and appliances industries, transport-equipment industry, precision-instrument industry.

Specifically, the new treatment procedure developed by MIDRC dramatically improves the stability of the alloys. Preliminary conventional results have already shown the improvements of the treated alloys.

The non-destructive neutron-diffraction measurements on KOWARI will provide spatially-resolved examinations of residual stresses through the full thickness of the thick cast components. The results will not only provide the understanding of MIDRC in-house manufacturing procedures but they will also be used to validate vital portable ultrasonic techniques.

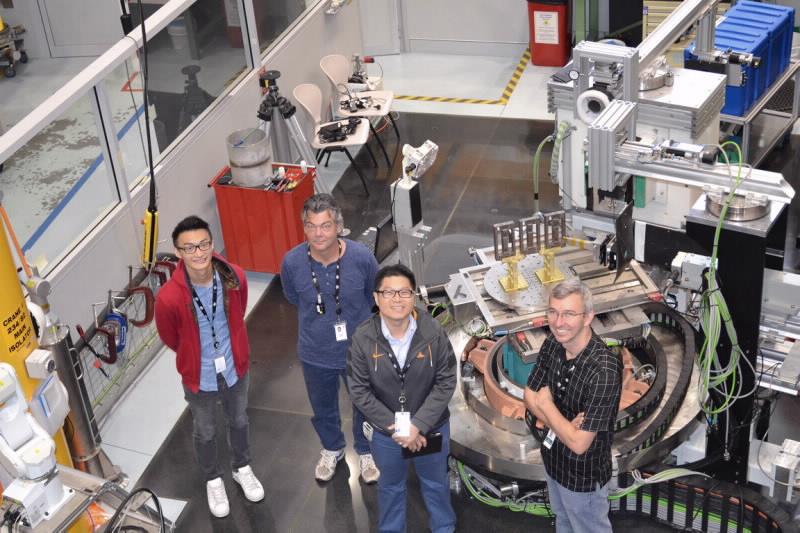

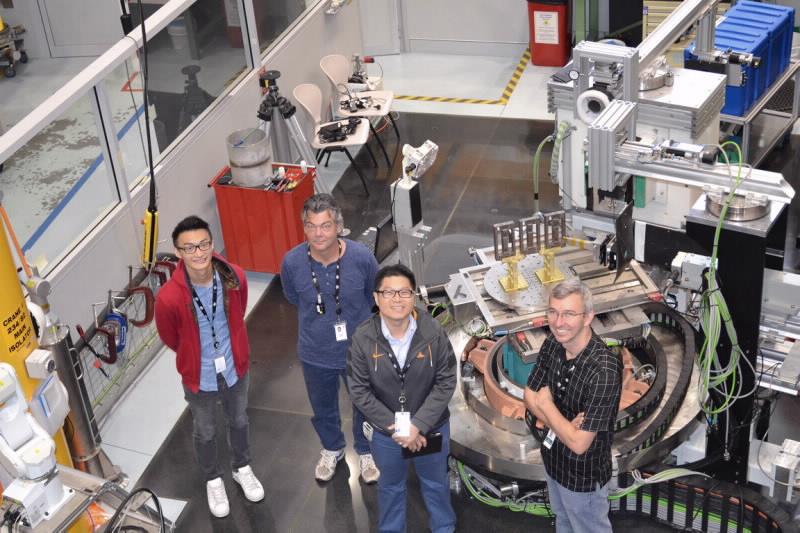

We are very excited to be a part of this highly collaborative project between Dr. Sung-Mao Chiu from MIRDC, Prof. E-Wen Huang of National Chiao Tung University and Dr. Shi-Wei Chen of National Synchrotron Radiation Research Center.

|

| In the KOWARI enclosure, from the left: student Shin-Min Shen; Dr Mark Reid ; Prof. E-Wen Huang; Dr Jason Gardner |