Published on the 12th June 2018 by ANSTO Staff

By carrying out micro-mechanical testing on single crystals of nickel, ANSTO materials researchers were able to derive the bulk properties of a polycrystalline material in a way that is useful for engineering.

Tensile properties are usually extracted from computational or sophisticated mathematical models following indentation or micro-cantilever testing, when the available material volume is small—such as in the case of thin film multilayers, ion irradiated materials and surface coatings.

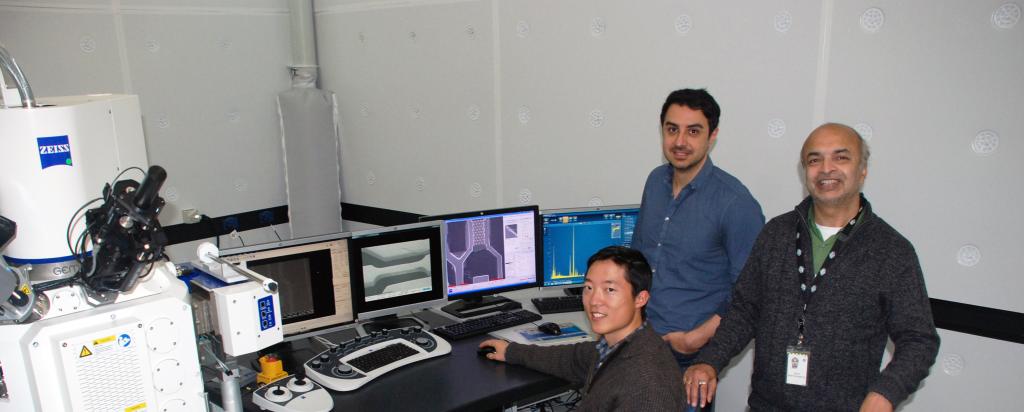

In a paper published in the International Journal of Plasticity, the investigators led by ANSTO senior scientist Dr Dhriti Bhattacharyya reported the results of in situ micro-tensile testing to evaluate the combined effects of strain rate and orientation on deformation behaviour in single crystals of nickel.

In these experiments, the effect of strain rate and crystal orientation were measured in 10 samples with 12 micron size.

Dr Alan Xu pulled the samples using a state-of-the-art micromechanical testing machine along a direction perpendicular to the cubic face of the crystal unit cell (100) and along the face diagonal of the unit cell (110) and measured the response.

The orientations were chosen because of the expectation of multiple slip on different numbers of slip systems.

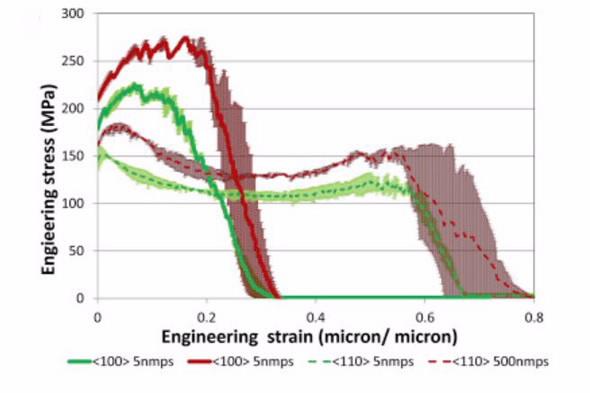

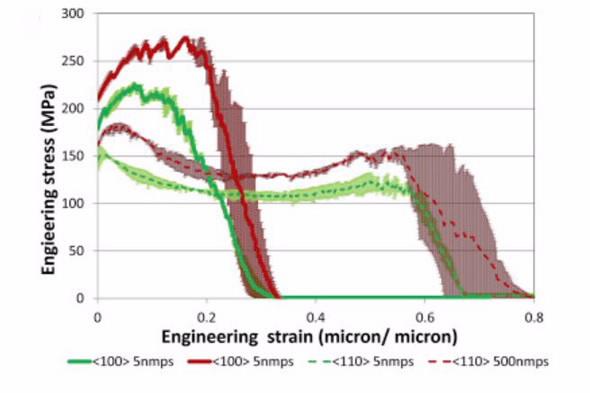

“We found different behaviours both in terms of the displacement, how the shape is deforming, but also in terms of the stress/strain curve,” said Xu.

The elongation of the <110> samples (as depicted above in video) was nearly double that of the <100> samples.

The stress/strain curve revealed that the <110> orientated sample exhibited an initial stress peak, followed by softening, a flat bottomed valley, a secondary hardening and peak and finally softening and failure.

“In this sample, the slipping occurs like the fanning out of a stack of cards,” said Bhattacharyya.

The double peak in a stress/strain curve is believed to be a unique phenomenon.

The investigators attributed this to an initial slip by a series of parallel slip steps along the whole gauge length. However, once the flow stress was increased due to strain hardening on this plane, accompanied by a rotation of the crystal, a second slip system on a different plane was activated.

The <100> oriented sample slips on at least two different planes initially (as depicted in video above); followed by four possible slip systems. Progressively more slip steps formed on multiple slip planes around the necked region to accommodate stress and the sample fractured in a knife edge-like manner.

Electron beam backscatter diffraction was used to identify the orientation of the crystals.

“The extent the crystals deviate from their original orientation is an indicator of how much the crystal itself has rotated,” said Xu.

“Pulling along both orientations showed that the ductility increased by twofold along the face diagonal, which was interesting,” said Bhattacharyya.

The critical resolved shear stress (CRSS), that is, the minimum shear stress required for plastic deformation along certain plane, was calculated from the yield stress of the <100> and <110> oriented single crystal samples to be ~73 MPa and ~63 MPa respectively.

The slight deviation of these values from CRSS values for nickel was thought to be attributable to effects due to difference in size and initial dislocation density. Dislocation density refers to the number of dislocations in a unit volume of a crystalline material.

“Importantly, the calculated strain rate sensitivity was found to be in the same order of magnitude as macroscopic samples of nickel,” said Bhattacharyya.

ANSTO materials researcher Michael Saleh used Taylor’s theory of polycrystal plasticity and the Hall-Petch theory of grain boundary strengthening with the flow stress strain data from the experimental single crystal samples In order to obtain approximate stress strain sensitivities for polycrystals.

“There was reasonable agreement between the predicted flow curve and the experimental curve,” said Saleh, who is an expert in computer modelling.

“If we wanted to get the flow stress for a 100 micron grain size, we can do that through this kind of modelling using plasticity theory, because the microscale response of single crystals complements the macroscale response.“

The next stage of research will involve testing of ion irradiated materials under similar testing conditions.

https://www.sciencedirect.com/science/article/pii/S0749641917305892