Dingo - Neutron Imaging

Neutron Radiography is the neutron analogue to X-ray radiography, as practiced in hospitals to detect broken bones, or in airports to detect metallic items like guns or knives in hand luggage. The only difference is that the neutron contrast between materials is different.

Whereas X-rays are good at seeing dense materials inside light materials (like bone in flesh, or metal in plastics or natural fibres), neutron radiography has traditionally been used to see hydrogenous materials inside metallic or ceramic objects.

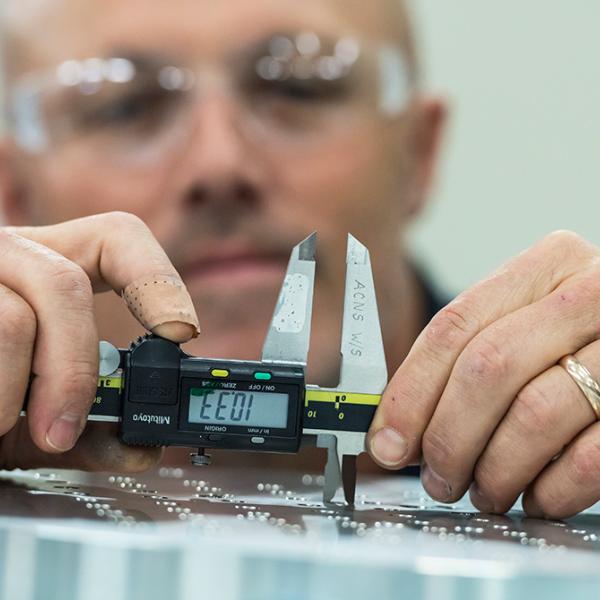

Classic applications include quality control on pyrotechnic devices like detonators, warheads, door thrusters in aircraft and explosive bolts for multi-stage rockets; detecting water damage in aircraft components, particularly composite wing structures; studying the content and flow of oil and water in sedimentary rocks, for instance from the North West Shelf; detecting problems with the flow of fuel and lubricants in aerospace or automotive engines, including fuel cells.

The other advantage the neutron can have over X-rays is its greater penetration through objects, so one can study relative large objects (up to and including complete aero-engines) using neutrons.

Neutron Tomography is the neutron analogue of the CT-scan in a hospital, in which a whole series of images is taken, and a full three-dimensional image of the object is reconstructed on a computer.

This can be very useful with very rare fossils or valuable ancient artefacts, as one may be able to see what is inside them, without destroying the object.

Our Dingo instrument is one of the highest intensity machines in the world, and is capable of making movies of the objects we study: for instance, running engines or motors, the flow of fluids in fuel cells, and so on.

Finally, there is a relatively new method of using the phase of the neutron (or X-ray) wave rather than its amplitude (as used in conventional hospital-style shadow radiography) to obtain different contrast, particularly from sharp edges or small objects. By virtue of the neutrons greater penetration, this might be particularly useful in imaging cracks in steel for instance.

We intend to pursue this phase-contrast radiography method using Dingo a number of groups in Melbourne are world-leading experts in these methods.

There is very good potential for strong industrial use of the Dingo Radiography/Imaging/Tomography Station, and we have in the past had discussions along these lines with companies in the defence, aerospace, steel, oil and gas, and non-destructive-testing industries.

Dingo was funded as part of the Australian Governments Super-Science Initiative, its conceptual design was completed in December 2009, and it is located on a thermal beam HB2 at the OPAL Reactor.

The Dingo instrument is named after the Australian mammal Canis lupus dingo.

Submit an instrument proposal

Instrument Advisory Team

Participants

Mark Hoffman (University of New South Wales) - spokesperson

Mark Easton (CAST-CRC, Monash University)

Erich Kisi (University of Newcastle)

Huijun Li (University of Wollongong)

Sherry Mayo (CSIRO imaging)

Rob O’Donnell (CSIRO Process Science & Engineering)

John Thornton (DSTO)

Les Bennett (Queens University, Ontario, Canada)

Burkhard Schillinger (FRM-II, Munich, Germany)

Peter Vontobel (Paul Scherrer Institute)

Lyndon Edwards (ANSTO )

Tim Payne (ANSTO )