Experiments at ANSTO have helped increase an understanding some of the viscoelastic properties of polymers through specific insights into the way polymers in the melt are entangled and disentangled in extensional shear and relaxation.

In research published in Physical Review Letters, Danish researchers reported on the extension of polymer molecules in filaments as they are extended and stretched and then suddenly quenched.

The research is important for understanding how polymers chains arrange and respond to flow. This is relevant to the processing of polymers.

Tube polymers

But the research is also relevant to understanding the complex dynamics and stability of liquid bridges, phenomenon such as the way in which a cat laps up milk, as pointed out by lead scientist Dr Kell Mortensen and a team at the University of Copenhagen in collaboration with researchers from the Technical University of Denmark.

Using small angle neutron scattering (SANS) on the Quokka instrument at the Australian Centre for Neutron Scattering in collaboration with Dr Chris Garvey (pictured below) and the Danish SANS-1 instrument at PSI in Switzerland, the investigators characterised the structure of branched polymers, known as POM-POMs or three arm star block co-polymers, when filaments were subjected to mechanical deformation under controlled flow.

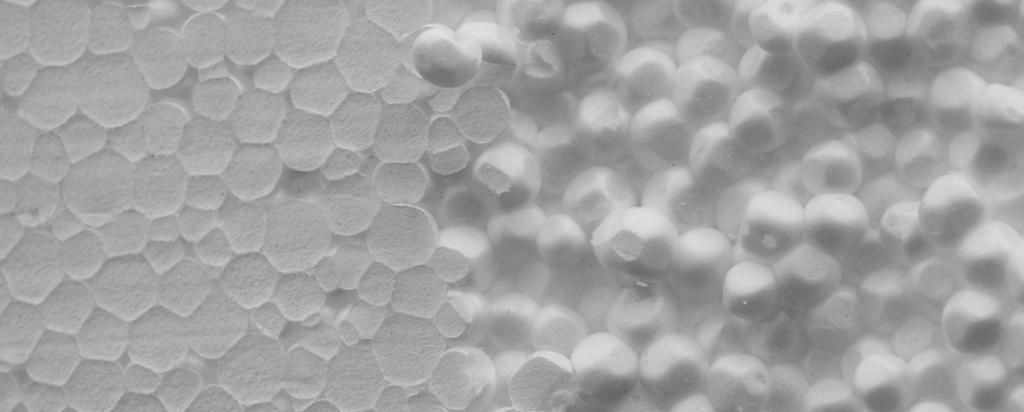

The material used was polystyrene, one of the most widely used packing materials, with deuterated ends.

The liquid bridges in the polymers were frozen by quenching at 10 K following melt processing.

A unique rheological instrument designed by an engineering group at the Technical University of Denmark maintained well defined rates of elongational flow at the centre of the filaments.

“This research is about how polymers behave in the melt, which is a transitory kinetic phenomenon,” said Garvey.

The experiment confirmed that the tube model for linear chains is applicable to three arm star block co-polymers in a relaxed state.

“We were able to measure the characteristic distances between the ends of the deuterated molecules, which give a clear simple picture of the alignment of the molecule in the flow direction,” explained Garvey.

“What we saw when the sample was sheared, was a highly stretched structure in which all three arms were parallel to the flow with one arm in one direction and the other two filament arms in the opposite direction on the flow axis,” said Garvey.

Long polymer chains in a melt or in solution are usually strongly entangled and isotropic in their natural state. After shear is removed they will return to their original entangled state.

Under normal polymer melt conditions, these processes happen extremely quickly, but the group was able to stop this process, and take snapshots of the relaxation process, by rapid cooling and “freezing in” molecular configurations for the experiment.

“What happens when you apply shear to a polymer and allow it to relax to different degrees is a fundamental question in polymer processing,” said Garvey.

“Quokka is the best instrument able to capture the structure in this type of investigation,” said Garvey.

"While results obtained from the two SANS instruments agreed perfectly, QUOKKA is the final port of call for these researchers because of its superior resolution and access to an extended range of length-scales."

The investigators point out that all dynamics of a star copolymer can be associated with a tube model but the characteristics explain distinct experimental results.

The samples were synthesised at the Department of Chemical and Biomedical Engineering at the Technical University of Denmark.

https://journals.aps.org/prl/abstract/10.1103/PhysRevLett.120.207801