Waste treatment case studies

Innovative waste technology with global applications.

RADIOPHARMACEUTICALS

Mo-99 waste facility at ANSTO

Due for practical completion in 2021, ANSTO is currently constructing a facility to treat waste from the new Molybdenum-99 (Mo-99) Manufacturing Facility. The waste treatment plant will also treat legacy waste from past production.

This flexible technology is capable of treating waste from past and future Mo-99 production and results in:

- Large volume reductions

- Reduction in transport and disposal costs

- Regulatory approval to build the expanded Mo-99 production facility was predicated on implementing a safe, secure waste management system.

REPROCESSING HISTORIC SPENT NUCLEAR FUEL

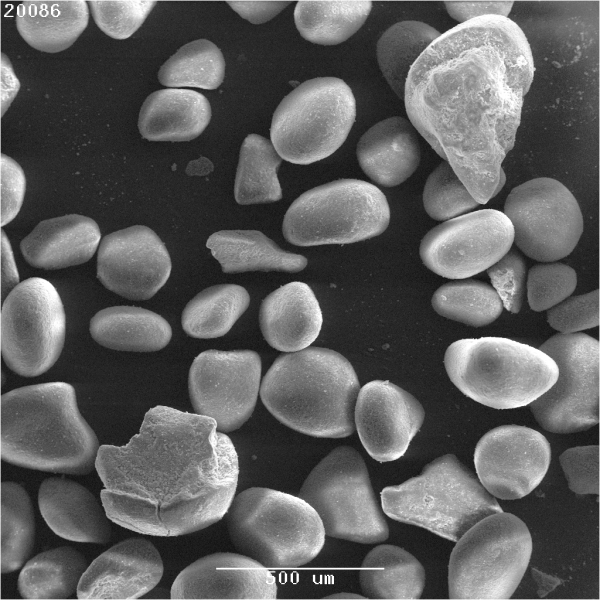

Idaho HLW Calcines

Multi-billion dollar lifecycle cost savings led to the US Department of Energy selecting ANSTO Synroc® as its preferred treatment technology.

The approximately 4400m3 of calcined reprocessed HLW, is very heterogeneous and consists of waste components that are very problematic to incorporate in glass. This significantly restricts possible vitrification waste loadings.

ANSTO developed tailored glass-ceramic waste forms that overcome these limitations and offer the following technical advantages:

- Extremely high waste loadings up to 80% (three times that of borosilicate glass)

- US$5 billion savings in Yucca Mountain disposal costs (DOE conservative internal estimates) compared to baseline vitrification technology

- Superior chemical durability able to meet relevant disposal requirements

- Process flexibility to accommodate highly heterogeneous compositions.