Published on the 13th April 2015 by ANSTO Staff

Over the last few days, Dr Wyman Zhuang and Dr Richard Djugum from the Aerospace Division at the Defence Science and Technology Organisation, supported by the KOWARI team investigated effectiveness of various repair technologies such as cold-spray and laser-cladding procedures in aluminum alloys used in aircraft structures and materials.

|

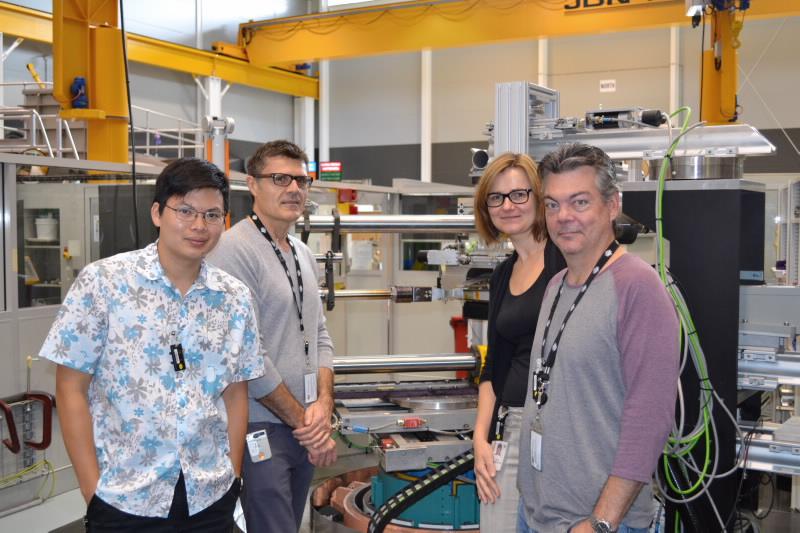

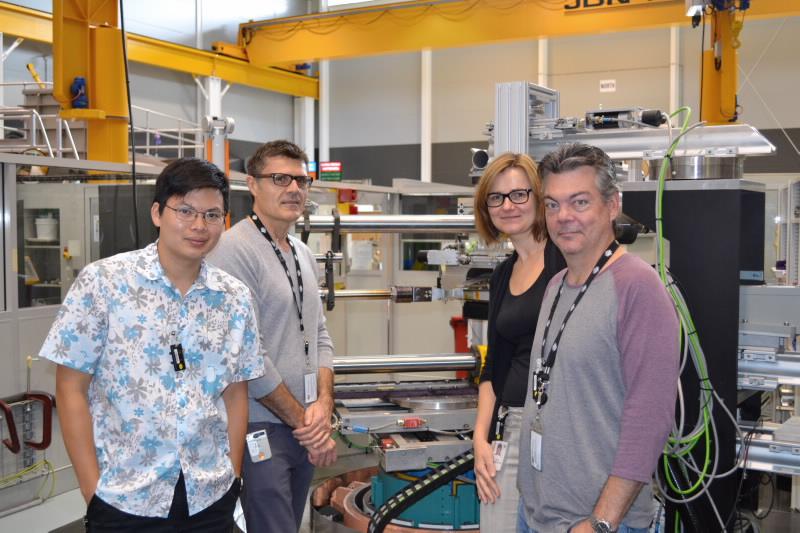

| Richard Djugum (DSTO, second from left) with Stanley Lee, Anna Paradowska and Mark Reid (left to right) beside the KOWARI Strain Scanner |

Among other KOWARI neutron diffraction experiments, The in-situ residual stress measurement (the test set-up as also shown in the photo) was focused particularly on Cold-Spray technology, which is a relatively new additive material deposition process capable of restoring the load-bearing capacity and fatigue strength of repaired corrosion-damaged metallic structures and components.

Residual stress relaxation can significantly influence the fatigue behaviour of aircraft repaired components, and it is important to observe and understand the relaxation mechanism of residual stresses in the repaired samples during fatigue testing in real time.

The results from this project will significantly improve current understanding and knowledge of the residual stress relaxation in the cold-spray repaired components under fatigue loading. This work is an important milestone for supporting the certification program of aircraft structural repair technologies for the Royal Australian Air Force fleet.