A world where windows doubling as TV screens and solar panels could be found in every home is a step closer today after researchers from Monash University and the Australian Synchrotron helped produce the most effective and highest frequency printable organic transistor in the world, potentially paving the way for the rapid mass-production of cheaper and more versatile electronics.

The new approach to printing thin, durable semiconductor sheets using the groundbreaking polymer P(NDI2OD-T2), revealed in Nature Communications by Italian researchers from the Center for Nano Science and Technology in Milan and which could one day see the replacement of bulky, silicon-based circuit boards, could hasten the development of translucent consumer electronics.

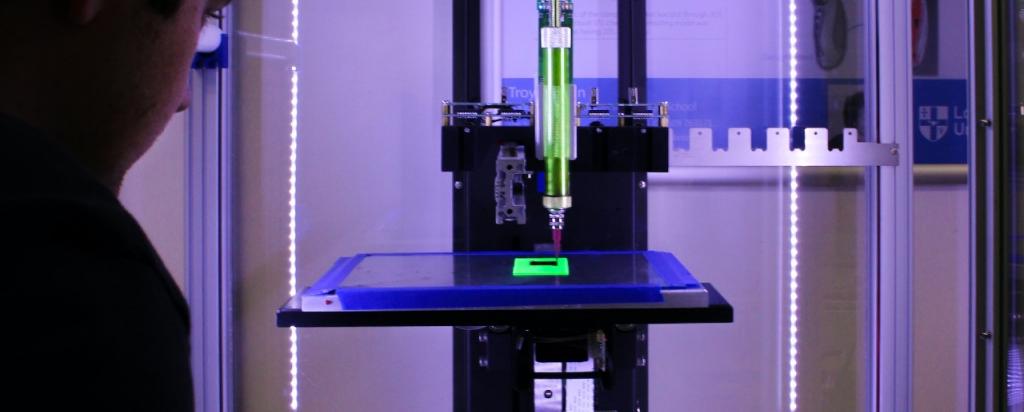

Associate Professor Chris McNeill from the Department of Materials Science and Engineering at Monash University, whose team used the Australian Synchrotron to inform a new ‘bar-coating’ printing technique, says while many research teams have attempted to realise industry-ready printed polymer electronics, they had not been able to match high-throughput printing with high performance.

‘We discovered that molecules in the polymer must be precisely aligned, leading to this new bar-coating approach, an improved approach to “roll-out” printing, in which the polymer solution is spread into a thin film, much like a mound of dough is rolled flat by a rolling pin.

‘The trick to achieving high performance was tightly wrapping a wire around the “rolling pin” bar, creating a coat of microscopic grooves 50 microns wide – one twentieth of a millimetre – which forces the molecules of the polymer into an organised pattern during printing, for much greater electron mobility.’

Using the bar-coating technique the research team achieved a printing speed of six metres per minute, up to 50 times faster than other approaches to printing that also control the polymer’s molecular arrangement.

Associate Professor McNeill says the Melbourne team provided crucial molecular analysis as the technique was developed.

‘Working at the Synchrotron’s Soft X-ray Spectroscopy (SXR) and Small and Wide Angle X-ray Scattering (SAXS/WAXS) beamlines we defined the optimal molecular structure of the polymer, enabling our Italian research partners to print a polymer transistor that is not only much larger than any predecessor, but boasts a commercially competitive frequency of 3.3 megahertz.

‘We believe the upscaling of polymer transistors will enable faster development of next-generation electronics that are flexible, malleable and more affordable, beyond the limitations of bulky silicon-based transistors.’

The first working silicon transistor, the fundamental building block of modern electronic devices, was developed in 1954.