Capability Summary and Techniques

In comparison to X-rays with lower energies, high-energy X-rays (≥ 45 keV) penetrate more deeply into matter, and are absorbed more weakly and scattered at smaller angles by the sample. This makes them particularly suited to the study of:

- Samples inside complex sample environments for in situ or operando studies

- Samples containing heavy elements where strong X-ray absorption is problematic

- Internal features of bulky samples, such as defects and strain

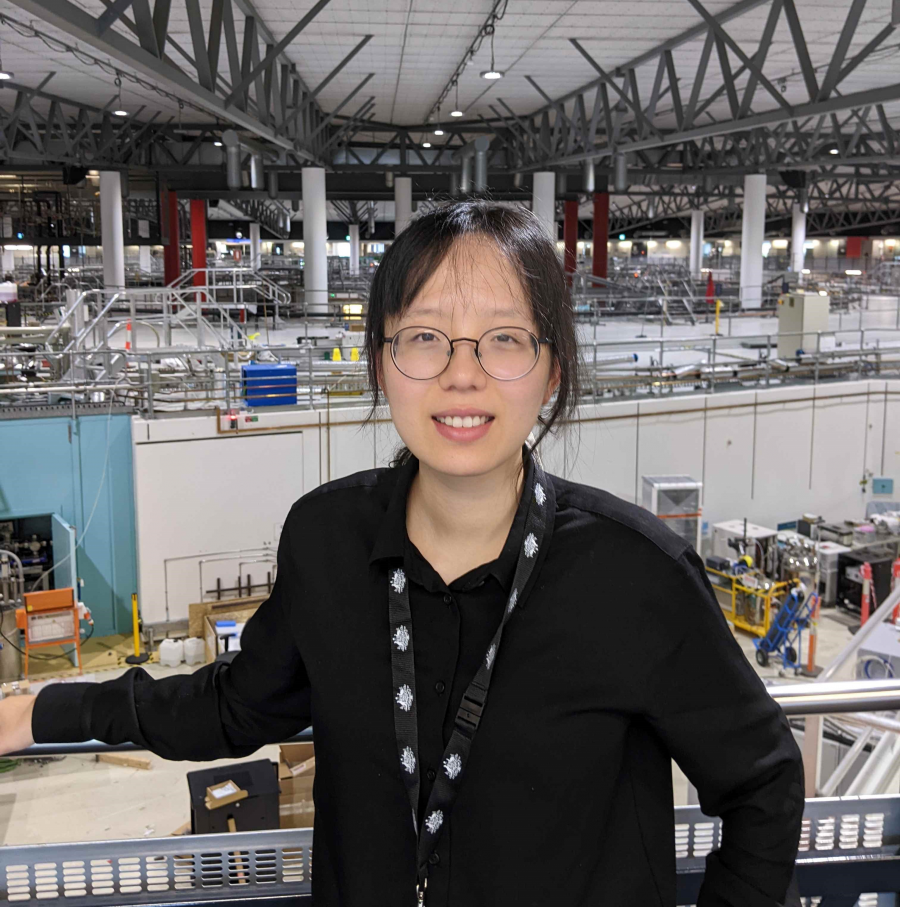

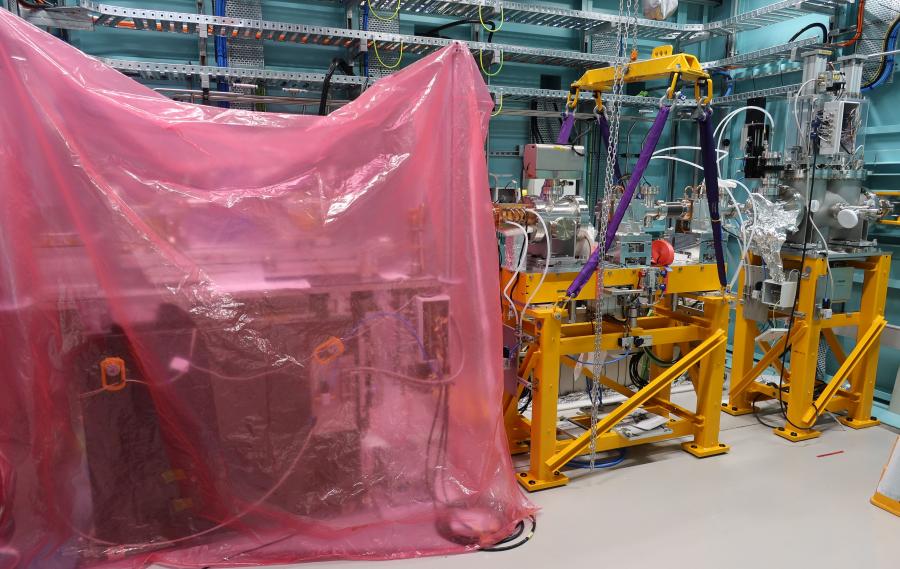

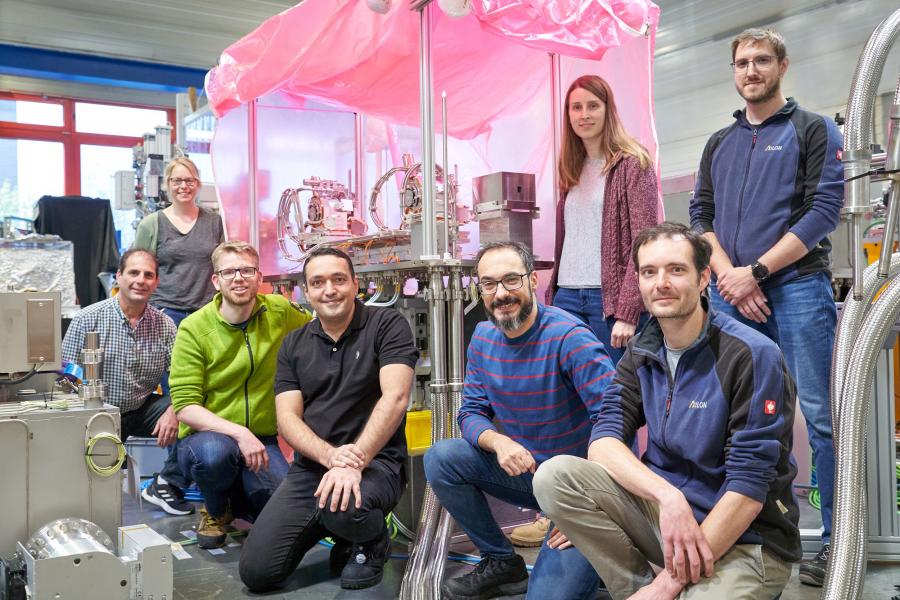

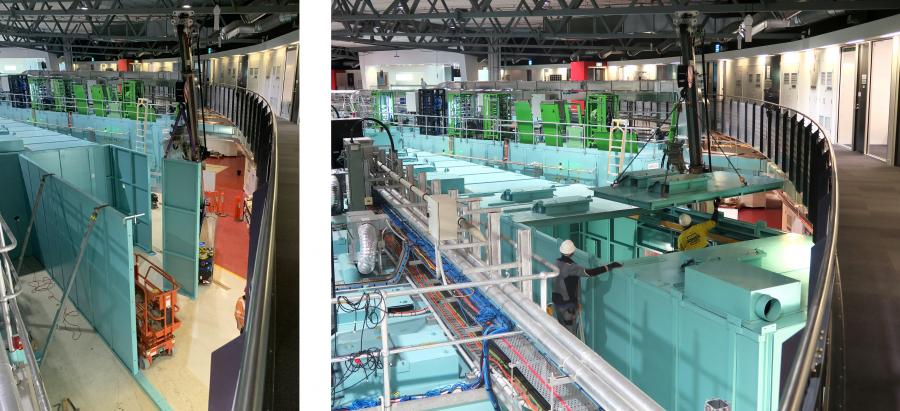

ADS-1 and ADS-2 will offer highly flexible experiment configurations and sample environments to enable a wide variety of materials characterisation experiments using high-energy monochromatic and polychromatic X-rays. The optics layout will maximise the flux at the sample position while offering variable beam sizes and focussing.

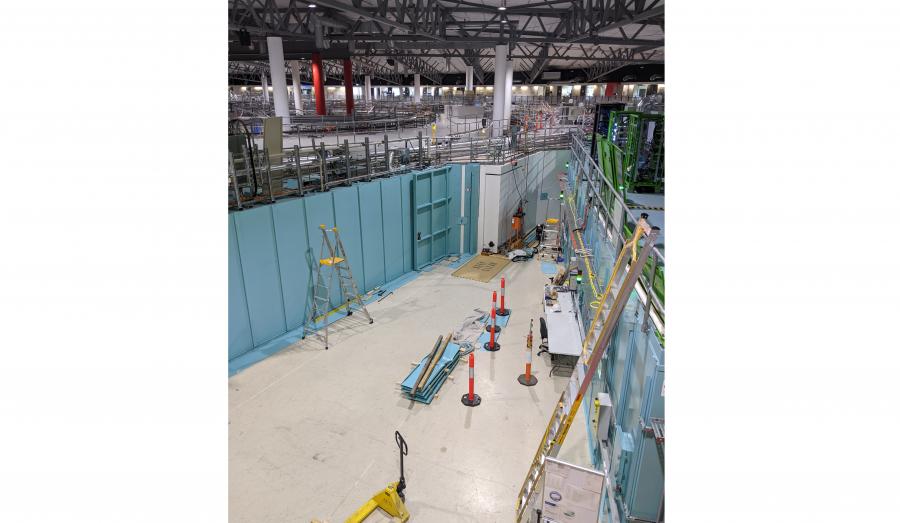

The planned timeline for the construction of ADS anticipates user experiments starting in 2026.

Techniques

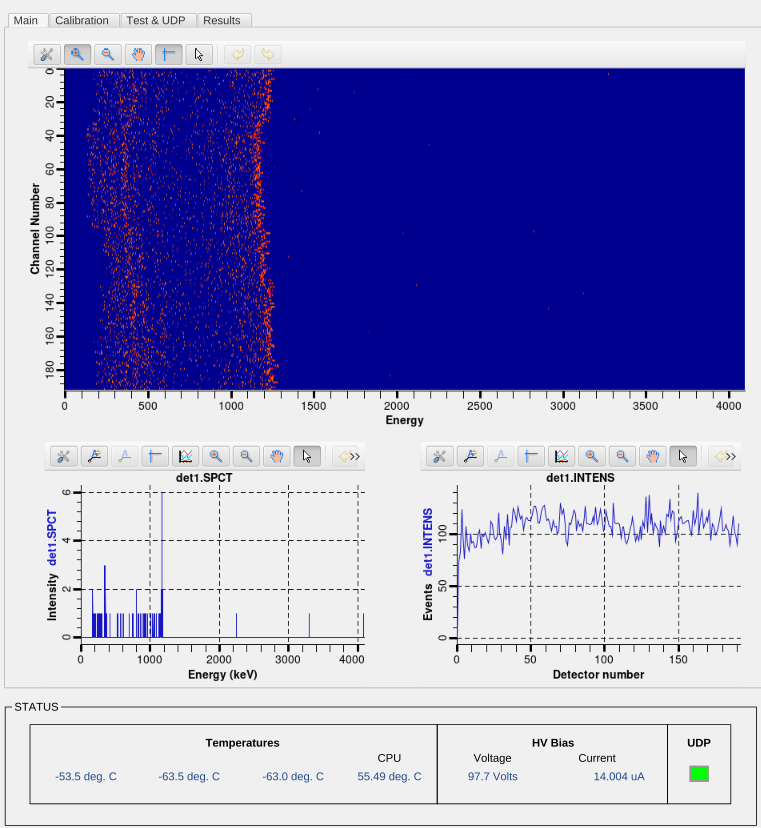

The capabilities of the ADS beamlines will include:

Monochromatic beam experiments

- Rapid in situ powder diffraction measurements using a range of sample environments (high/low temperature, high pressure, gas flow, etc.) with the benefits of increased sample penetration and high momentum transfer

- Total scattering measurements (PDF) for samples with short-range ordering

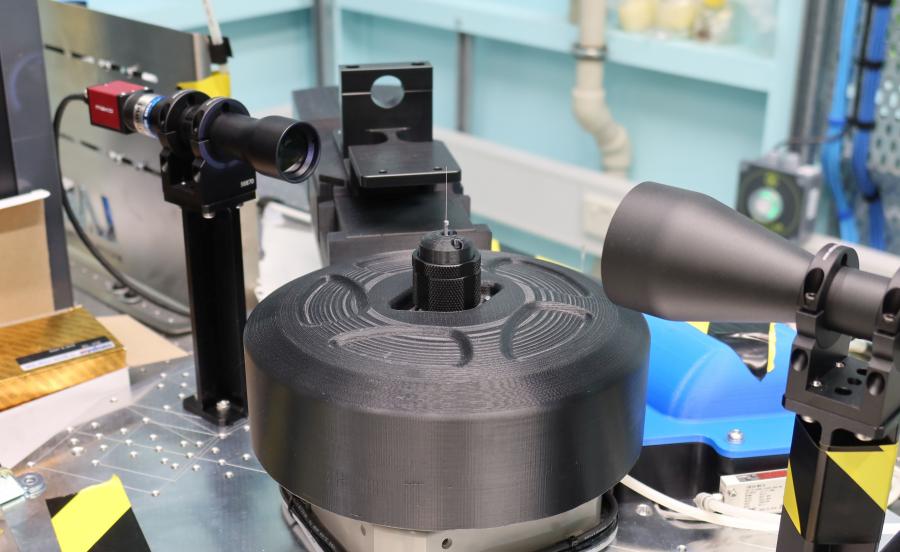

- Single-crystal diffraction experiments on large and/or strongly absorbing crystals, or crystals in complex sample environments with limited angular access for the beam (e.g. diamond anvil cells, furnaces)

- Rapid texture analysis and 2D materials mapping

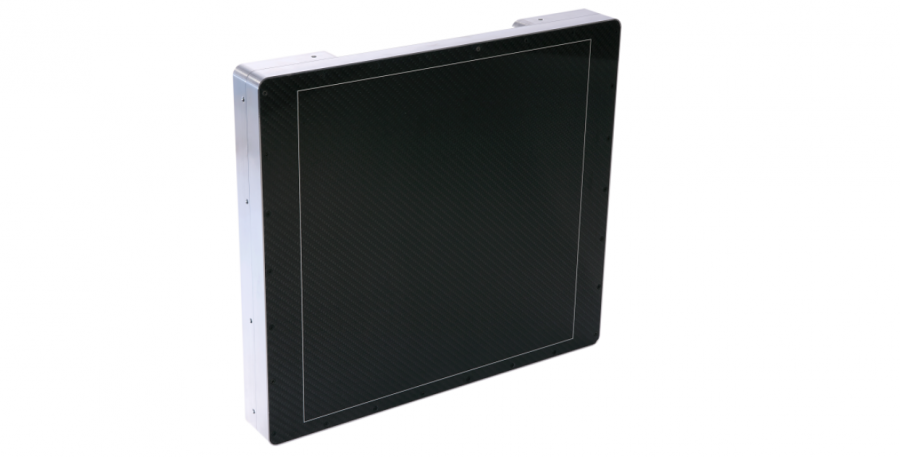

- Imaging and tomography

White beam experiments (ADS-1 only)

- Energy-dispersive diffraction and high-resolution 3D strain scanning

- Imaging and tomography

- Laue diffraction

Endstations

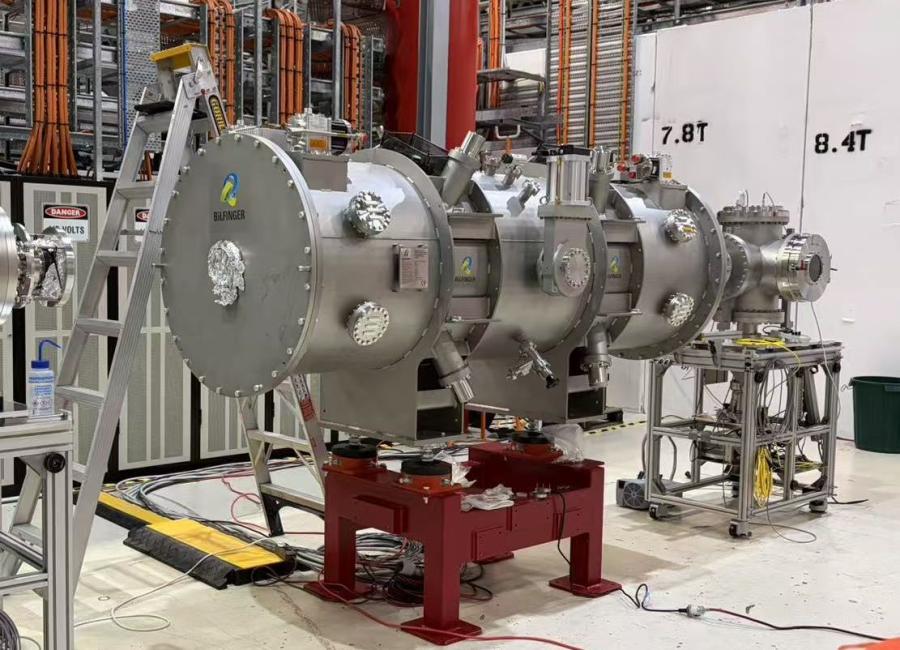

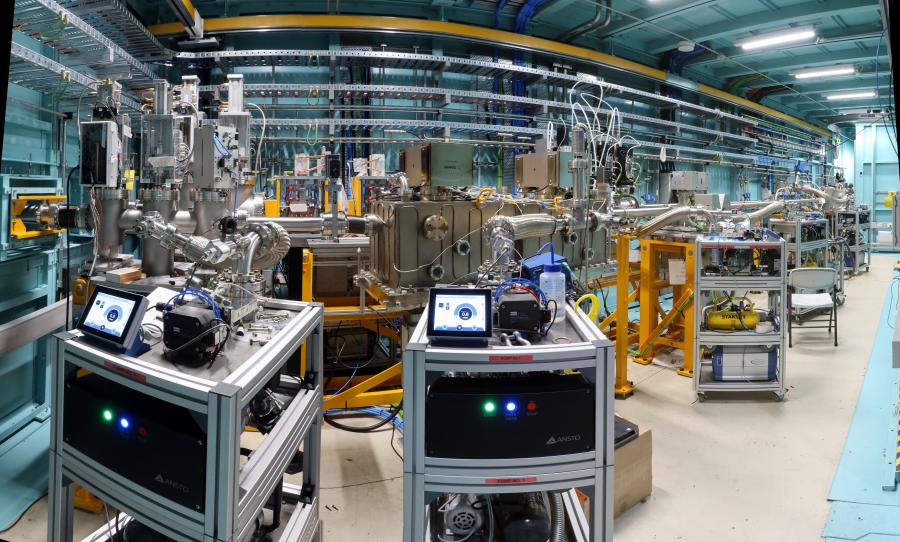

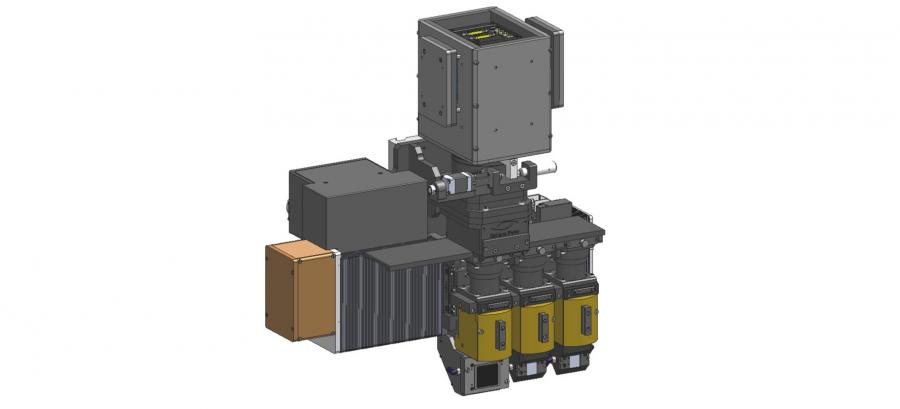

The ADS high-energy X-ray beam will be split using a side-bounce monochromator to serve two independent beamline endstations, ADS-1 and ADS-2.

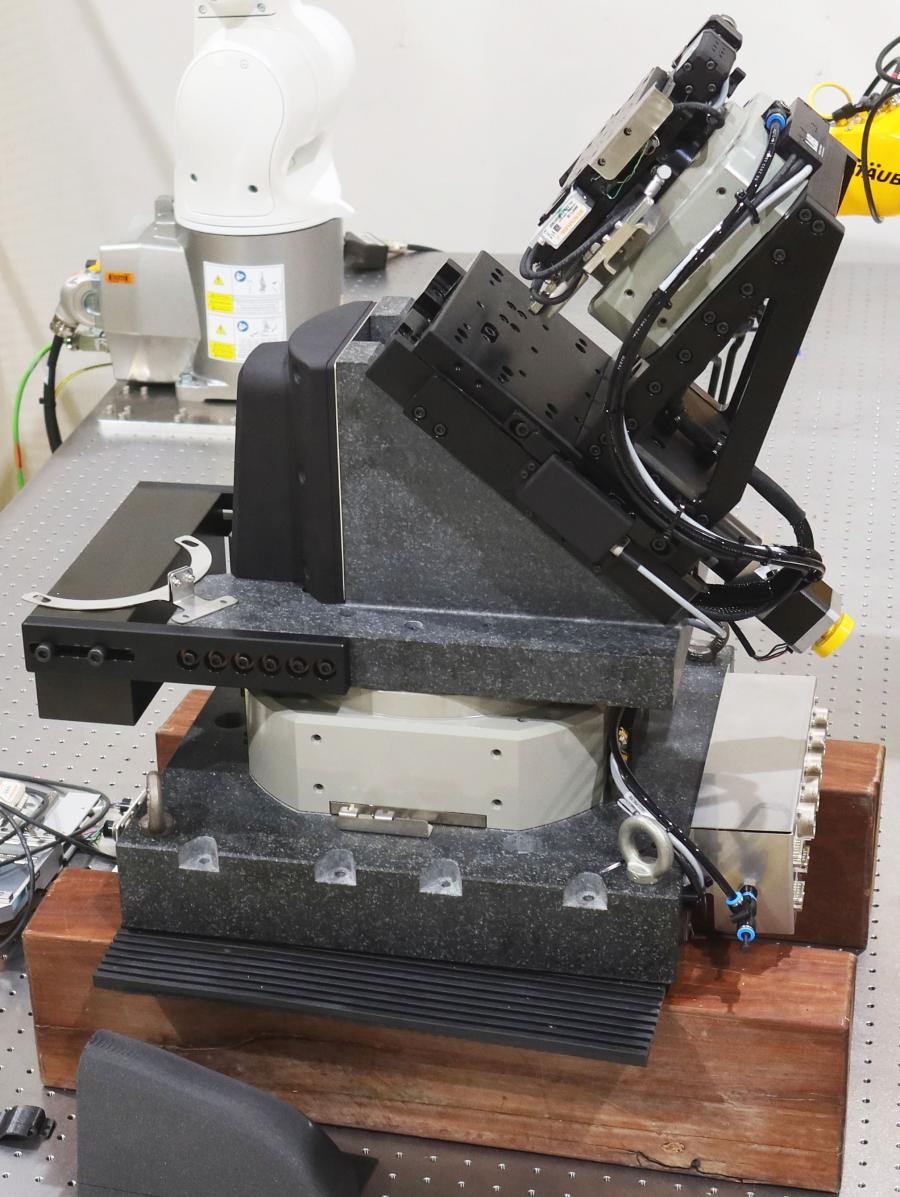

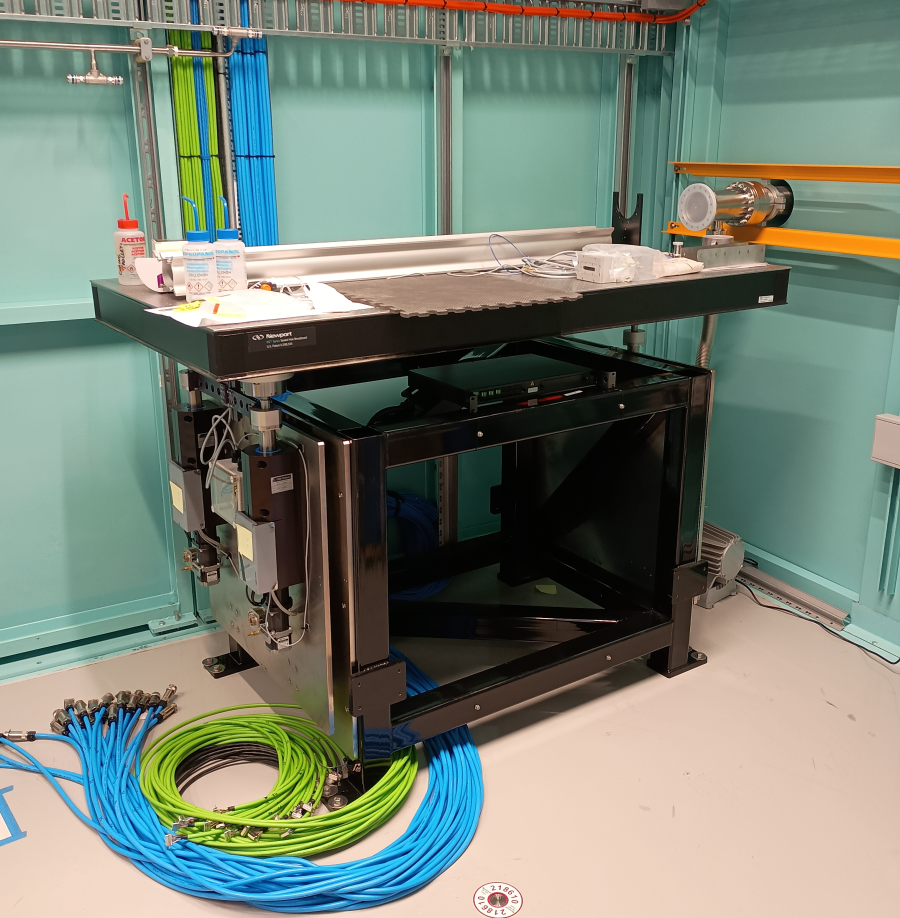

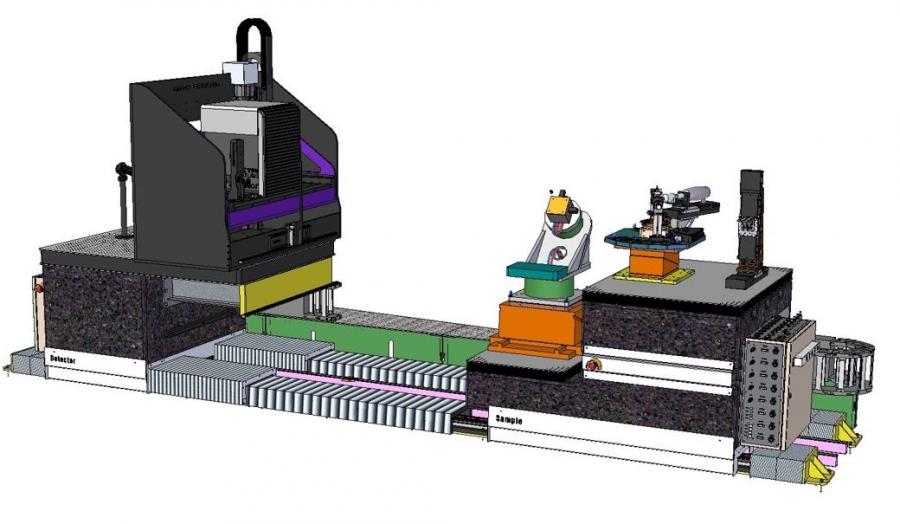

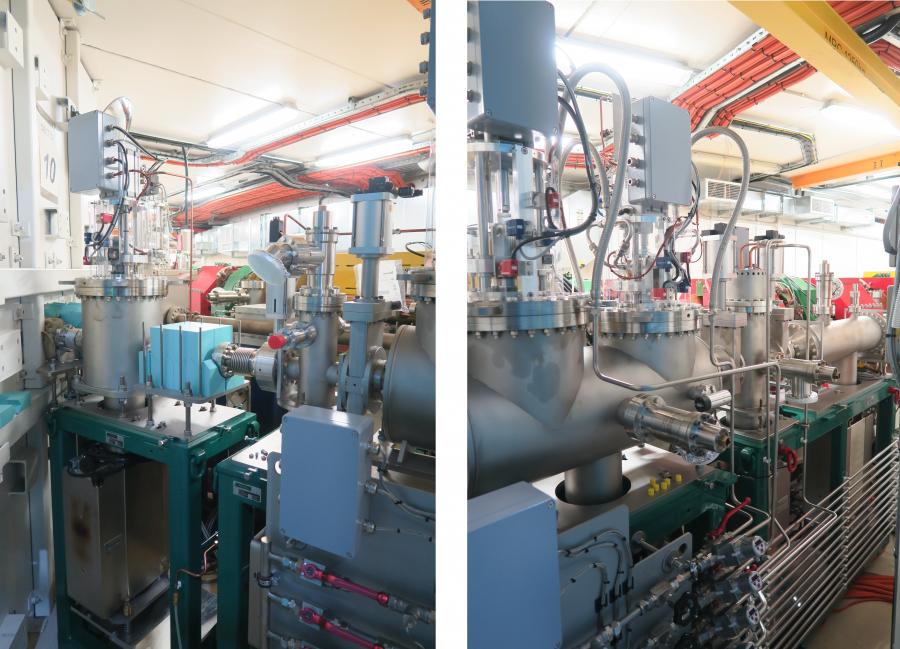

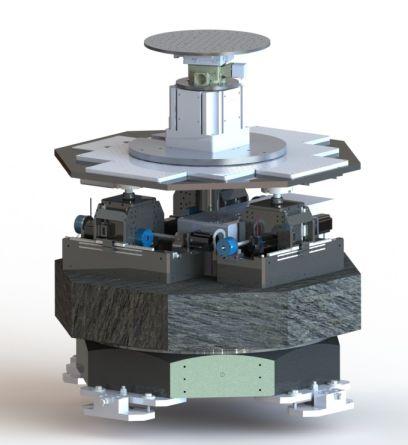

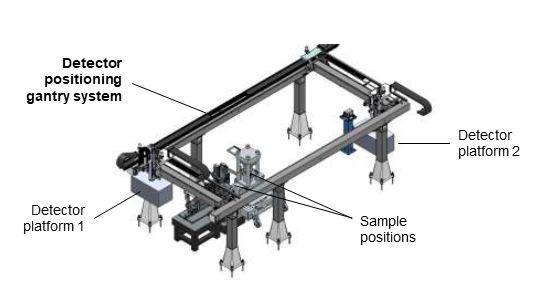

ADS-1 will offer white and monochromatic X-ray diffraction and imaging capabilities with a monochromatic energy range of 50 – 150 keV. A multipurpose array of detectors with a highly flexible positioning system (sample–detector distances of 0.3 – 4 m) will facilitate a wide range of experiments, including those combining multiple data types (e.g. diffraction and imaging). The ADS-1 sample stage assembly will support loads of up to 300 kg and offer fast rotation speeds suitable for tomography. Larger user-supplied equipment can also be accommodated. A range of flux, band-pass and beam size options will be available depending upon energy and optical configuration.

ADS-2 will be capable of monochromatic diffraction experiments at three fixed X-ray energies (45, 74 or 87 keV). It will be suited to techniques such as powder diffraction, single crystal diffraction, total scattering (Pair-Distribution Function analysis) and high-throughput applications with a range of standard sample environments. The ADS-2 sample stage assembly will accommodate samples and environments of up to 100 kg.

Both beamlines will have controlled hutch environments, multiple standard sample environments spanning a wide temperature range, gases available for experiments, and a fume extraction system.

For further information, see ADS Technical Specifications.