Capabilities

Process Development

Rare earths

Our team has extensive experience in processing monazite, bastnasite and xenotime, as well as sources such as apatite, ionic clays and complex ores containing zirconium / niobium silicates.

Talk to one of our expertsOur experience includes:

- sulfation baking

- caustic conversion

- alkaline roasting

- selective precipitation

- impurity removal

- solvent extraction

- ion exchange

- process water treatment (softening)

- chemical concentrate production

- deportment and management of radioactivity

Find out more about our work in rare earth processing.

Lithium

Our team has undertaken a significant amount of work on the processing of lithium brine and hardrock deposits to produce saleable lithium chemical concentrates.

Talk to one of our expertsOur experience includes:

- sulfate and chloride roasting

- brine evaporation

- leaching

- purification / neutralisation

- crystallization

- ion exchange

- battery grade product production

- membrane separation

- electrolysis

- water treatment unit processes

Review our capabilities in lithium processing.

Critical & Strategic Metals

Our team are experienced in mineral processing, hydrometallurgical and pyrometallurgical processing of specialty metals including zirconium, niobium, scandium, titanium, molybdenum, tungsten, gold and silver.

Talk to one of our expertsOur experience includes:

- recovery of gold from anode slimes

- recovery of scandium from nickel laterite deposits

- recovery of scandium as a by-product of rare earth and

- mineral sands processing

- recovery of niobium (oxide) and conversion to ferroniobium

- recovery of zirconium and conversion to ZOC, ZBS and zirconia

- production of high purity HfO2 (>99.8%) from mixed Zr/Hf

- feedstock

- recovery of vanadium from carnotite ores

- recovery of vanadium via acid leach/SX

Review our processing of critical and strategic metals capabilities.

Uranium

ANSTO is home to Australia’s leading uranium process development facility with expertise in the processing of all uranium ores.

Talk to one of our expertsOur experience includes:

- leaching involving acid and alkaline, heap and in-situ

- solvent extraction (mixer-settler and pulsed column)

- ion exchange (fixed and fluid bed, and Resin-In-Leach and Resin-In-Pulp)

- product precipitation

- impurity control (including radioactivity)

- reagent recovery / recycling via membrane technologies

- process water treatment (including nanofiltration and reverse osmosis)

Read more about our uranium processing project work.

PILOTING

Piloting operations

Our pilot plant operations are key to our service offering, and play a leading role in transferring the results of laboratory test work programs to industry.

Talk to one of our expertsCapabilities:

- processing

- flexibility to adapt

- reactors, thickeners, filtration equipment supporting all aspects of hydrometallurgical processing

- multiple rotary kilns for most baking and roasting applications

- various sized solvent extraction circuits

- all style ion exchange contractors

- vertical (1 to 6 m) and horizontal leach columns

- continuous nano-filtration rig

Review more details about our pilot and demonstration plants.

SEPARATIONS

Ion exchange

ANSTO has dedicated laboratory and modular pilot plant equipment to conduct all types of batch and continuous test work. These facilities and equipment have supported numerous uranium, lithium, critical / speciality metal and base metal projects.

Talk to one of our expertsOur facilities and equipment include::

- fixed and fluidised bed – batch and continuous rigs

- Resin-In-Pulp – batch and continuous rigs (1 to 5 L contactors)

- continuous ion exchange carousel (500 mL columns)

- resin attrition and chemical stress testing

Find out more about our ion exchange capabilities.

Membrane separation

We evaluate and design membrane separation systems including nanfiltration, microfiltaration, microfiltration, ultrafiltration and reverse osmosis for a diverse range of feed solutions.

Talk to one of our expertsOur facilities and equipment include::

- laboratory flat sheet aparatus

- commercial scale spiral wound membrane pilot plant

- scale-up from laboratory to industrial size plant

- development of alternative economic processes

Find out more about our membrane separations technologies.

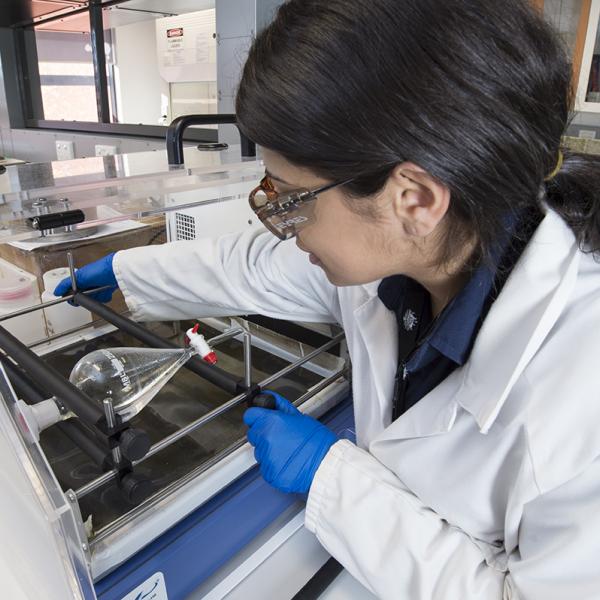

Solvent extraction

We provide solvent extraction for the purification of metals such as uranium, rare earths, base metals, and zirconium / niobium / hafnium. Our facilities include well equipped laboratories and a purpose built mini-pilot plant with mixer-settlers that can be specifically configures to test any solvent extraction process.

Talk to one of our expertsOur experience includes:

- rare earths separations – chloride and sulphate media

- extraction of zirconium from niobium and hafnium

- uranium extraction from saline leach liquors

- separation of base metals – copper, cobalt/nickel and zinc

- control of radioactivity in copper anode slimes – gold SX process

Review our solvent extraction capabilities.

FACILITIES

Mineralogy

We provide identification and characterisation of uranium, rare earth, base metal, lithium, and other value containing minerals, and their associated gangue assemblages.

Talk to one of our expertsOur services:

- phase identification

- phase quantification – modal mineralogy (incl. size by size)

- phase liberation – quantification and evaluation

- mineral association – quantification and evaluation

- modal mineralogy – size by size

Find our more about our mineralogy facilities.

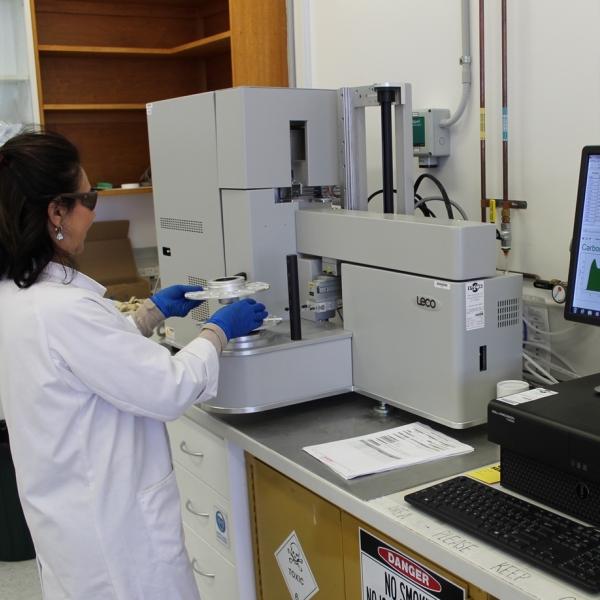

Radioanalytical

ANSTO has built a reputation as a world-leader in radioanalytical expertise.

Talk to one of our expertsOur primary radioanalytical techniques:

- gamma spectrometry

- alpha spectrometry

- delayed neutron activation (DNA) analysis

- neutron activation analysis (NAA)

Find out more about our radioanalytical capabilities.

Helpful links

For further information