Published on the 24th February 2022 by ANSTO Staff

Key Points

-

Energy researchers from UNSW have reported progress using controlled architectural design and structural engineering to fine-tune an intercalation pseudocapacitor for electrochemical storage in portable devices

-

Nanoflakes on cerium oxide, synthesised to a consistent thickness, were implanted with molybdenum ions to improve properties

-

The ion implantation was undertaken at ANSTO's Centre for Accelerator Science

Energy researchers from UNSW have reported progress using controlled architectural design and structural engineering as a method to fine-tune materials to have simultaneous high power and high energy density for electrochemical storage in portable devices.

The designed material that consists of nanoflakes of cerium oxide synthesised to a consistent thickness and implanted with molybdenum ions at ANSTO’s Centre for Accelerator Science has demonstrated promising characteristics for use as an intercalation pseudocapacitor.

Dr Pramod Koshy, Dr Sajjad S Mofarah, Mr Xiaroran Zheng and associates in the School of Materials Science and Engineering at the University of NSW, the Solid State Physics Laboratory in Bangladesh and ANSTO have reported on the fine-tuning of oxygen vacancy ordering and channel formation in cerium oxide implanted with molybdenum ions to achieve intercalated pseudocapacitance.

The results have been published in the journal ACS Applied Materials and Interfaces.

The group was building on work that commenced in 2017. An earlier paper published in Nature Communications in 2019 first described ultrathin

CeO2−x for pseudocapacitive energy storage applications.

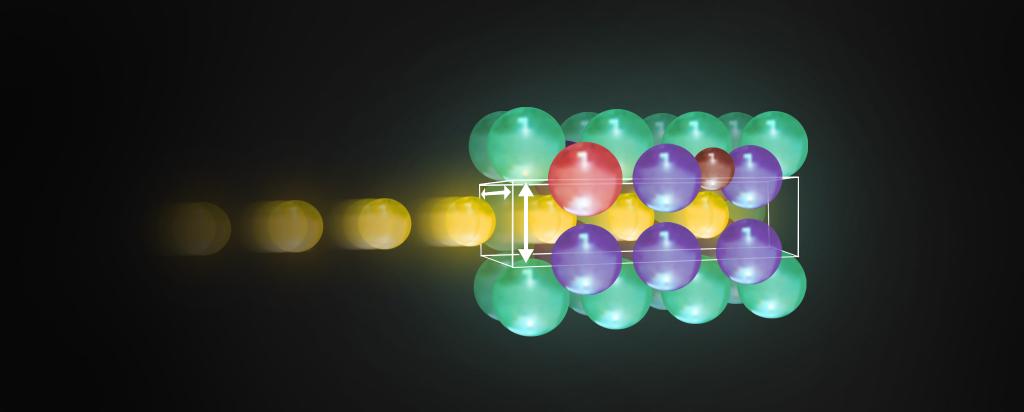

In the most recent work, the investigators made structural modifications to the transition metal oxide by fabricating two-dimensional nanoflakes of defect-rich cerium oxide, which are as thin as 12 nanometres on a nickel foam substrate.

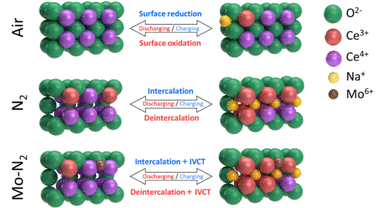

Intrinsic defects were introduced into the nanoflakes by applying reduction conditions through an N2 atmosphere.

“Our first strategy was the creation of oxygen vacancies in the system by using a reducing atmosphere,” explained co-first author Dr Mofarah of UNSW.

Nanoflakes have high surface to volume ratios and short cross-sectional pathways that enhance ionic charge transfer processes.

The surface engineering was directed to the formation of ordered oxygen vacancy channels (array of 0D point defects) that provided an atomic channel for intercalation.

The presence of stable oxygen vacancy channels with a significantly higher number of active sites at the surface and subsurface regions in the nanoflakes improved capacitance.

The role of defects was investigated in the electrodeposited CeO2−x by annealing both under air or N2.

Reduction increased the gravimetric capacitance by 77 per cent.

Simulations using theoretical modelling validated that surface reduction led to the formation of ordered oxygen vacancy channels.

“It wouldn't be very effective as a pseudocapacitator unless it was two dimensional. Ideally, with a nanolayer of atomic thickness, you have all the active sites to contribute to the charge/discharge process, since there is no difference between bulk and surface, “ said Dr Mofarah.

Investigators used the low energy ion implanter beamline on the Sirius accelerator at ANSTO's Centre for Accelerator Science to implant low energy ions of molybdenum Mo6+ into the two-dimensional material.

Instrument scientists Dr Armand Atanacio and Dr Madhura Manohar carried out the ion implementation process.

It is believed to be the first use of ion implantation to improve the performance of an intercalation pseudocapacitator.

“Most of the time our accelerators are used for analysis to characterise a material. Low energy ion implantation is different as it modifies a material, changing its functional surface properties, “ said Dr Atanacio.

The introduction of molybdenum atoms into the crystal structure generated electrons that facilitated charge transfer, enhancing overall electroconductivity.

“This was our second strategy to bombard the cerium oxide layer with metal ions, in this case, molybdenum, to improve the conductivity of the system. Some of the cerium is believed to be removed from the system during this process,” said Dr Koshy.

“We use low energy so we can put in low concentrations. Also, the technique doesn’t destroy the surface,” said Dr Koshy.

The generation of electrons did not alter the energy band but facilitated enhanced electron transfer across the band gap.

Molybdenum ion implantation and reduction processes increased the specific capacitance by 133 per cent while the capacitance retention increased from 89 to 95 per cent.

Without the architectural and structural modifications, cerium oxide would be unsuitable as a pseudocapacitor, since it has a densely packed crystal structure of a non-stratified nature and has only two oxidation states (i.e., Ce3+ and Ce4+) which can switch to one another during charge/discharge process.

“No one has seen this behaviour from cerium oxide and that was because of the structural modifications that we did on the material, “ said Dr Mofarah.

The group intends to experiment with other ions to see if capacitance can be improved further.

DOI: https://doi.org/10.1021/acsami.1c14484

Intercalation capacitors

Intercalation pseudocapacitors are advanced energy storage devices that store electrochemical energy.

Pseudocapacitance describes an electrochemical mechanism that originates from faradaic charge transfer processes across the electrode/electrolyte interface.

Intercalation is the reversible inclusion or insertion of an ion/molecule into compounds with layered structures.

Intercalation pseudocapacitance is a mechanism that stores energy into the bulk of electrode through a battery-like intercalation process